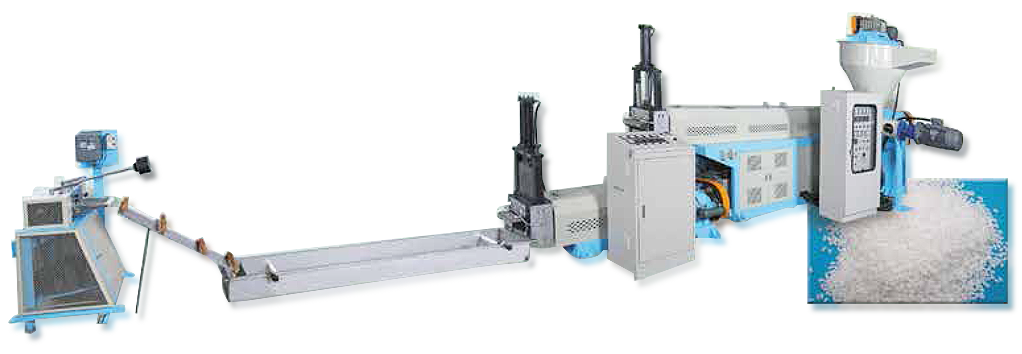

EPS, EPP, EPE, EPO Recycling Machine

3-in-1 integrated operation from 1.crushing, 2.conveying, 3.feeding to extrudingEPP/EPS/HDPE /LDPE Two-Step Plastic Recycling Machine

Mechanical Specifications :

| Suitable for plastic | EPS-EPE-EPP | EPS-EPE-EPP | EPS-EPE-EPP |

| Extruder capacity {kg / per hour) | 80-100 | 100-150 | 150-250 |

| First Extruder Machine | |||

| Screw diameter | 100mm | 125mm | 150mm |

| Screw ling ratio (L / D) | 32:1 | 32:1 | 36:1 |

| Driving motor (Two-stage variable speed gear box) | 60HP | 75HP | 100HP |

| Automatic thermo | 7paragraphs | 7paragraphs | 10paragraphs |

| Funnel Force-feed motor | 5HP | 5HP | 5HP |

| Side Force-feed motor | 10HP | 15HP | 15HP |

| Hydraulic motor | 3HP | 5HP | 5HP |

| Second Extruder Machine (With frequency converter) | |||

| Screw diameter | 100mm | 125mm | 150mm |

| Screw ling ratio (L / D) | 8:1 | 8:1 | 10:1 |

| Driving motor | 20HP | 25HP | 50HP |

| Automatic thermo controller | 4paragraphs | 4paragraphs | 4paragraphs |

| Water cooling tanks {Material} | SUS 304 | SUS304 | SUS304 |

| L*W*H | |||

| Pelletizer(With frequency converter) | |||

| Diving HP | 5HP | 7.5HP | 7.5HP |

| Weight | 3,800kg | 4,800kg | 6,500kg |

Machine Specifitions are subject to change without prior notice.

Note: on behalf of the recovery of compressed Li Long brick, according to the market price recovery compression, hot-melt Poly-Long brick.